-

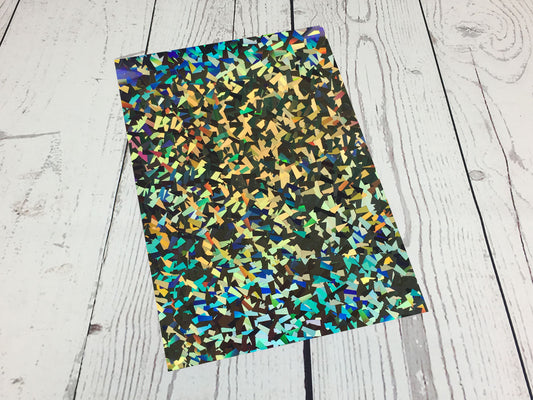

Fashion plotter film - DIN A4 - purple sparkle

Regular price €1,26 EURRegular price€1,80 EURSale price €1,26 EURSale -

Powerflex plotter film - DIN A4 - skin

Regular price €1,37 EURRegular price€1,95 EURSale price €1,37 EURSale -

Fashion plotter film - DIN A4 - silver sparkle

Regular price €1,26 EURRegular price€1,80 EURSale price €1,26 EURSale -

Powerflex plotter film - DIN A4 - pastel pink

Regular price €1,37 EURRegular price€1,95 EURSale price €1,37 EURSale -

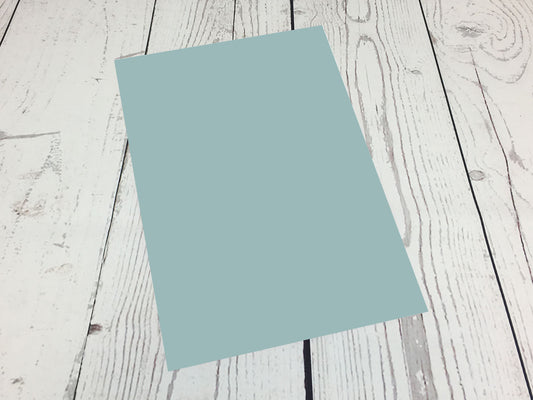

Powerflex plotter film - DIN A4 - pastel blue

Regular price €1,37 EURRegular price€1,95 EURSale price €1,37 EURSale -

Powerflex plotter film - DIN A4 - burgundy

Regular price €1,37 EURRegular price€1,95 EURSale price €1,37 EURSale -

Powerflex plotter film - DIN A4 - signal red

Regular price €1,37 EURRegular price€1,95 EURSale price €1,37 EURSale -

Chameleon plotter film - DIN A4 - green

Regular price €1,79 EURRegular price€2,55 EURSale price €1,79 EURSale -

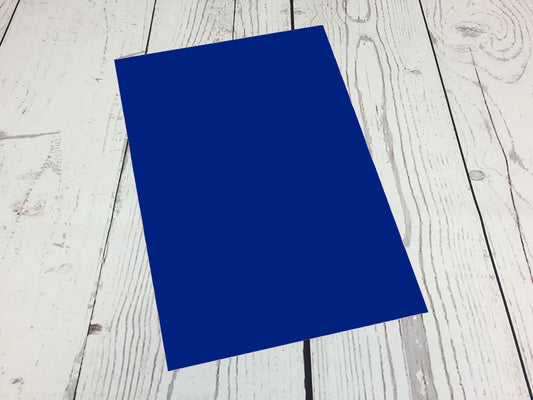

Powerflex plotter film - DIN A4 - royal blue

Regular price €1,37 EURRegular price€1,95 EURSale price €1,37 EURSale -

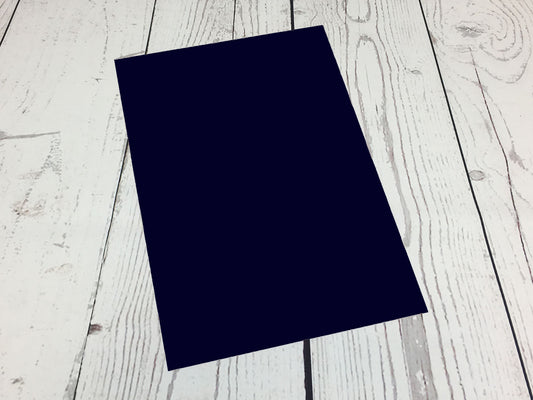

Powerflex plotter film - DIN A4 - marine

Regular price €1,37 EURRegular price€1,95 EURSale price €1,37 EURSale -

Powerflex plotter film - DIN A4 - pastel purple

Regular price €1,37 EURRegular price€1,95 EURSale price €1,37 EURSale -

Chameleon plotter film - DIN A4 - blue

Regular price €1,79 EURRegular price -

Fashion plotter film - DIN A4 - crystal

Regular price €1,26 EURRegular price€1,80 EURSale price €1,26 EURSale -

Powerflex plotter film - DIN A4 - green

Regular price €1,37 EURRegular price€1,95 EURSale price €1,37 EURSale -

Powerflex plotter film - DIN A4 - apple green

Regular price €1,37 EURRegular price€1,95 EURSale price €1,37 EURSale -

Chameleon plotter film - DIN A4 - red

Regular price €1,79 EURRegular price€2,55 EURSale price €1,79 EURSale

Collection: plotter films

Everything about our plotter film – flex film

What is plotter film and what formats are available?

Plotter film, the material for cutting plotters, is a one-off transfer film for transferring to textiles. The process as a whole is called transfer printing. We have Oeko-Tex certified flex film for plotting in numerous colors and with various color effects as A4 format or, on request, as rolls/meter goods. The film width of the plotter film on the roll is 50cm.

Flex films are relatively thin, often single-colored plotter films that are also available with various color effects or color patterns. The hot melt adhesive for applying the plotter film to the textile is activated by pressure and heat. Plotter films and especially flex films are primarily used for labeling and finishing fabrics. Due to the low material thickness, flex film is particularly suitable for textiles, as it remains quite flexible after application to the carrier material due to its special properties and therefore lasts a particularly long time compared to other textile films.

Which plotter films are available in terms of appearance and effect and what is their intended use?

Here you can find branded plotter film as flex film for textile design in the following formats:

- Powerflex - single-colored textile films

- Neon - vibrant bright colors

- Fashion - fashionable trendy patterns

- Glitter/Glitter - glitter and sparkle effects

- Chameleon - color change with shimmer

- reflector foil - direct light reflection

Plotter film is ideal for decorating and labeling casual clothing such as T-shirts, sweatshirts, pullovers or for enhancing sportswear and accessories such as jerseys or sports bags or for creative or promotional marking of work clothing. The range of applications for textile film is very wide and offers all imaginable creative possibilities.

Plotter film application and care

How is flex film used and applied?

Flex film is a textile film activated by heat and pressure. The plotter film often consists of several layers: a carrier film at the bottom, a color film layer with pigments in the middle and a top layer of hot melt adhesive. The reflector film has another protective film that must be removed before cutting!

When cutting using a cutting plotter, the cut is made on the cover layer, the carrier film is not cut through. As a result, the motif or lettering must be cut in reverse. The cutting plotter is therefore the first choice for cutting, but simple motifs can also be cut in or cut out using a cutter knife or scissors.

A press is recommended when applying the patch, but it is also possible to apply it with an iron. It is important to ensure that the fabrics to which the patch is to be applied are heat-stable. It is best to test a scrap piece beforehand to see if the fabric is suitable. Cotton and cotton blends are generally very suitable.

Multi-colored motifs can also be created. 4 to 5 layers of flex film are often possible. A maximum of 3 layers of plotter film is usually recommended. To do this, it is necessary to adhere to the required color sequence and to pay particular attention to ensuring that the bottom textile film does not overheat, as it must withstand several pressing processes. To ensure this, it is recommended to initially press the bottom plotter film for only up to 5 seconds, then remove the carrier film and then apply the next layers. The final layer is then pressed for another 15-20 seconds.

The general procedure for the press and iron when applying to the carrier fabric pre-washed without fabric softener differs slightly:

For the version with a press, it is recommended to pre-press the material for 1-3 seconds to remove any remaining moisture from the fabric for a great result. Pressing is done at a temperature of around 150°C to 165°C, with a pressing time of 10-20 seconds and an average pressure of 4 to 5 bar. The carrier or transfer film is then removed while still warm by carefully peeling it off. There are exceptions, however, such as neon foil, glitter foil, fashion foil and reflective foil. For these types, the carrier film should only be removed after cooling for optimal results. Please follow the respective instructions here. If the result is not yet as desired, you can press it again using baking paper or a cloth, for example. After pressing, please allow the work to cool down lying flat.

When pressing with an iron, a firm surface must be chosen. The ironing board usually gives too much and is therefore unsuitable. A wooden cutting board or similar is often very suitable for this. Please only set the iron to medium heat, for example level 2. Pressing is done without steam! The motif or lettering is placed on the fabric with the top layer of hot melt adhesive and fixed with the shiny carrier film facing upwards. The whole thing is then covered with a suitable material such as baking paper or cloth. It is important not to iron the motif on under any circumstances, but to press it on completely using an iron under medium to strong pressure, gradually by offsetting and again for 10-20 seconds per section. At the end, remove the carrier film at the recommended temperature according to the instructions. If necessary, press again using baking paper. Here, too, please allow the result to cool flat.

What needs to be taken into account when it comes to textile care when using flex film?

Depending on the version, flex film as a plotter film can be washed at up to 60°C, but the washing instructions for the respective carrier material should also be observed. Please turn the plotted garment inside out before washing. Please do not put it in the dryer. Only wash it 24 hours after it has been applied for the first time. The use of fabric softener or liquid detergent can have a significant impact on durability.

After washing, please iron the motif or lettering only on the wrong side using a protective medium (baking paper or fabric) carefully at low heat, for example on level 1.

If the motif or writing comes off over time, it can usually be re-pressed using baking paper and an iron.

We hope you have fun plotting with our flex film.